And, I am happy with it because all pieces join together pretty well =) Although, I spent quite a bit of time on this tutorial, doesn't matter. What's done is done ...

Showing posts with label Vase. Show all posts

Showing posts with label Vase. Show all posts

Monday, 3 August 2009

090803 Vase Physical Model

Today I finally get my laser cut done and put them together. Gave the vase a flat white spray paint finish for aesthetic purpose.

Saturday, 1 August 2009

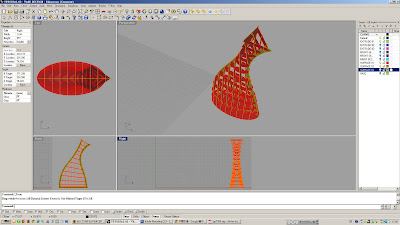

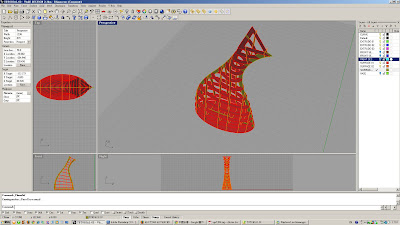

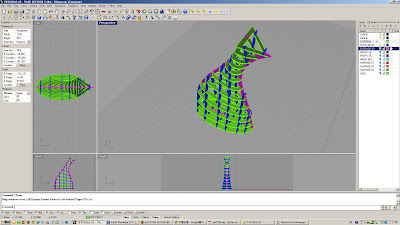

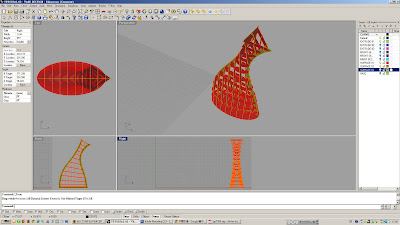

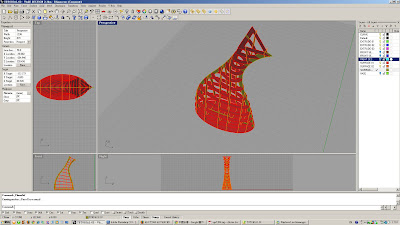

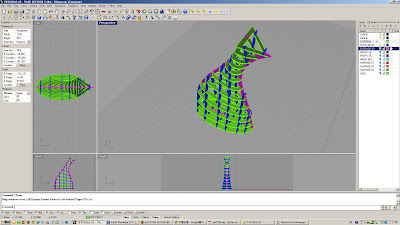

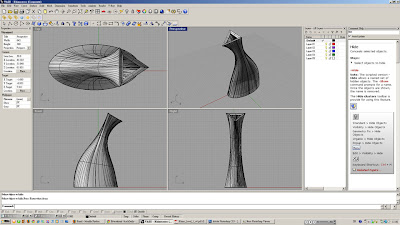

090731 Vase Matrix Using Section

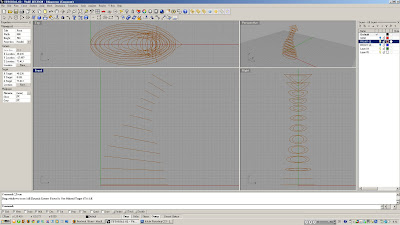

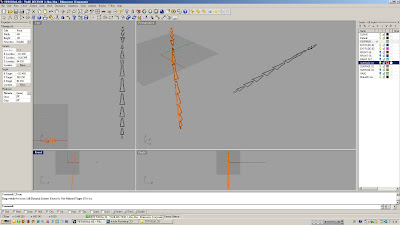

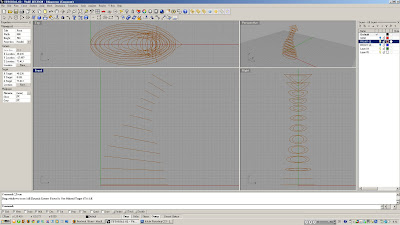

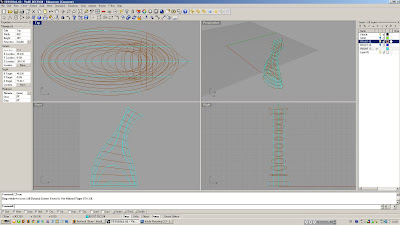

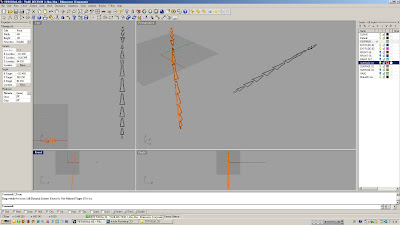

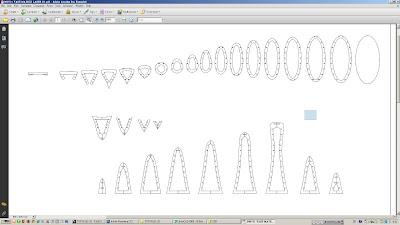

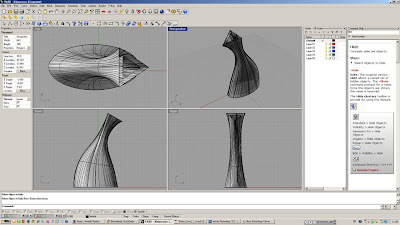

We are to create a matrix using the command "SECTION" in rhino. The sections will then translate into cad format for modification on joints. Then, print the cad drawing to pdf for 2d laser-cut.

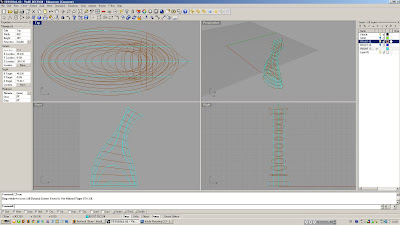

Step 01:

- Open vase model in rhino

Step 02:

- From front view, create sections with an incremental angle from bottom to top

Step 03:

- Create vertical sections every 10mm

Step 04:

- The vase might not be able to hold itself esp. the neck

- Created more sections with 5mm increment

Step 05:

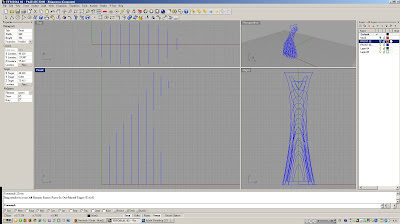

- Try creating vertical sections from right viewport

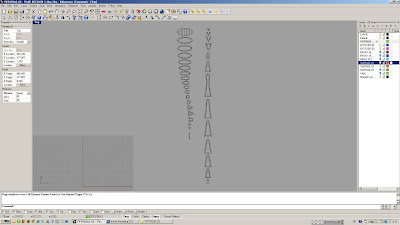

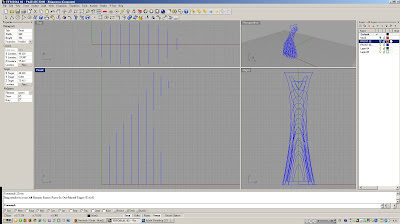

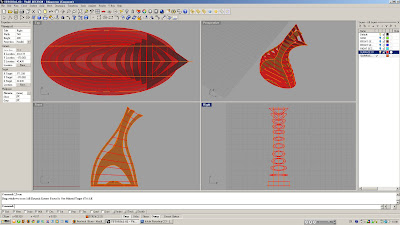

Step 06:

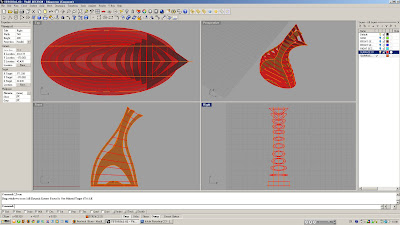

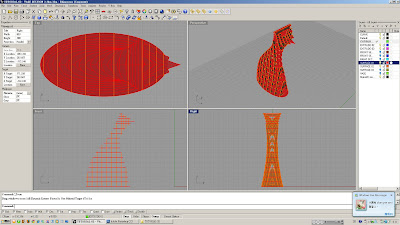

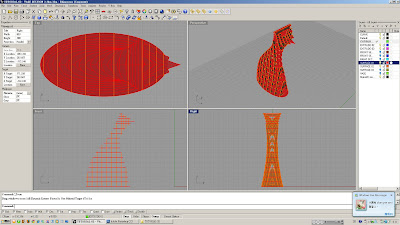

- Create surfaces from planar curve(s)

Step 07:

- Extrude surfaces by 0.5mm on both sides cap on

- Consider using 1mm strawboard, hence such extrusion

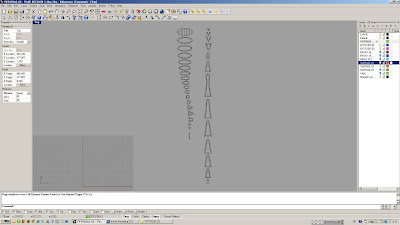

Step 08:

- Variation 01

Step 09:

- Variation 02

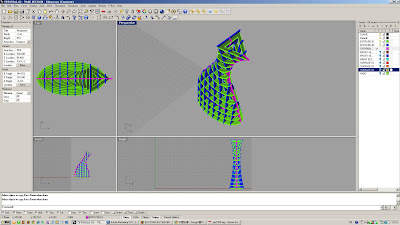

Step 10:

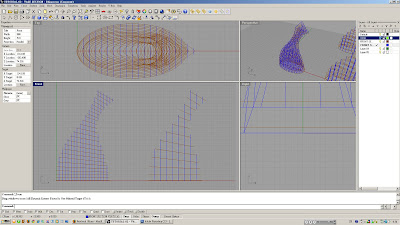

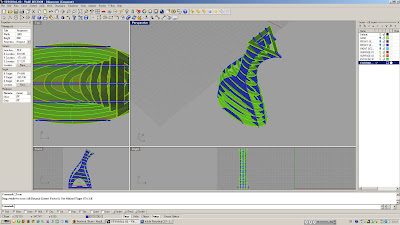

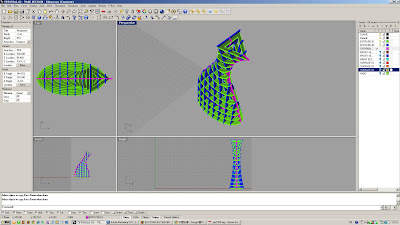

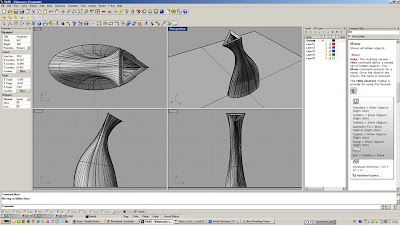

- Ultimately, orthogonal horizontal and vertical sections from front viewport was chosen

- Create more sections closer to the top to increase structural stability

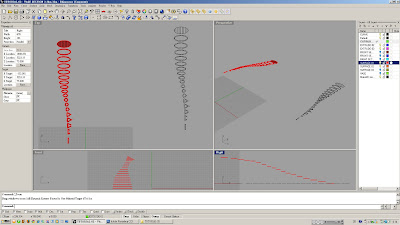

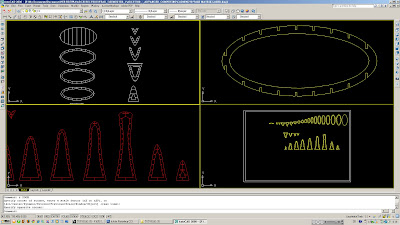

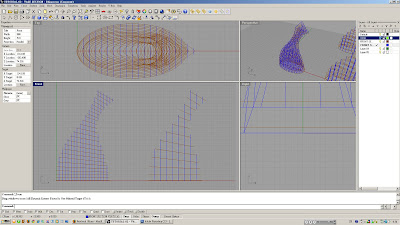

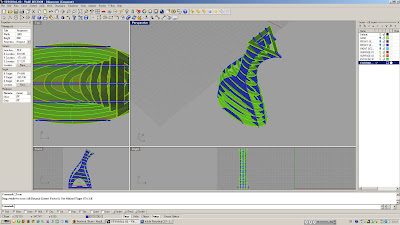

Step 11

- I think using extrusion and boolean difference will mess up the model by having weird cutout, etc. Therefore, I only use surfaces and the command intersection to create intersection curves on surface for flatten

- After intersecting surfaces, hide vertical elements.

- Lay out horizontal sections with curves across the top view

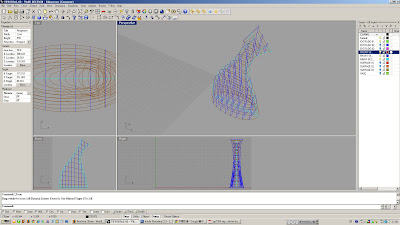

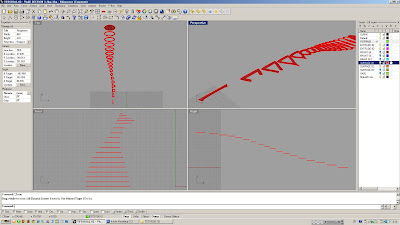

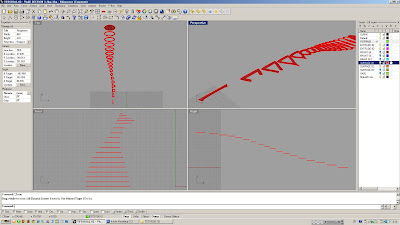

Step 12:

- Use command "Make2D" and select all visible surfaces

- A set of lines will be created on z=0

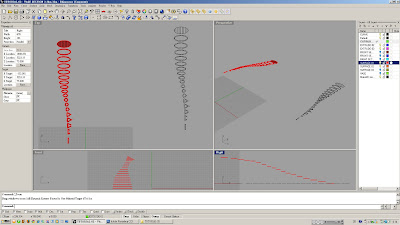

Step 13:

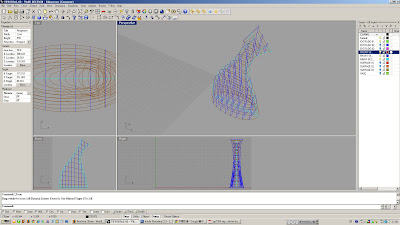

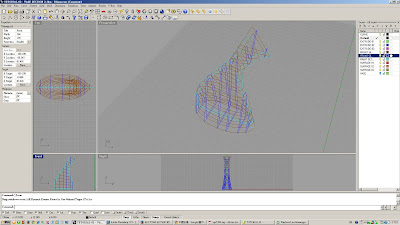

- Do the same for the vertical sections

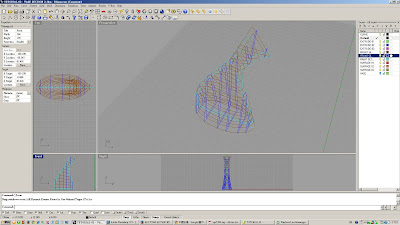

Step 14:

- Remove/hide unwanted elements, leaving only the lines for "export to cad format"

Step 15:

- Create joints (think of how the pieces should be joined together)

- I use clipping system for my vase, i.e. split the vertical sections into half such that they can clip onto the horizontal sections.

Step 16:

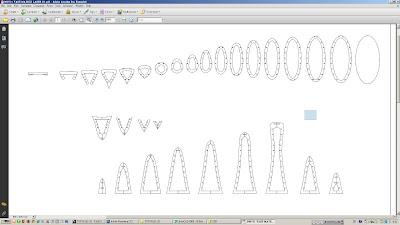

- Create PDF(s) for laser-cut

The appointment for laser is on Monday morning 11am. I hope everything goes well without major accident. More images after completion.

Step 01:

- Open vase model in rhino

Step 02:

- From front view, create sections with an incremental angle from bottom to top

Step 03:

- Create vertical sections every 10mm

Step 04:

- The vase might not be able to hold itself esp. the neck

- Created more sections with 5mm increment

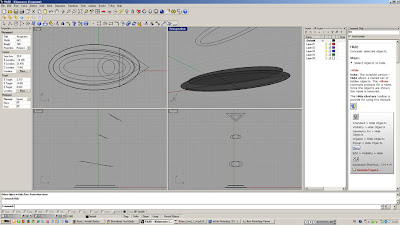

Step 05:

- Try creating vertical sections from right viewport

Step 06:

- Create surfaces from planar curve(s)

Step 07:

- Extrude surfaces by 0.5mm on both sides cap on

- Consider using 1mm strawboard, hence such extrusion

Step 08:

- Variation 01

Step 09:

- Variation 02

Step 10:

- Ultimately, orthogonal horizontal and vertical sections from front viewport was chosen

- Create more sections closer to the top to increase structural stability

Step 11

- I think using extrusion and boolean difference will mess up the model by having weird cutout, etc. Therefore, I only use surfaces and the command intersection to create intersection curves on surface for flatten

- After intersecting surfaces, hide vertical elements.

- Lay out horizontal sections with curves across the top view

Step 12:

- Use command "Make2D" and select all visible surfaces

- A set of lines will be created on z=0

Step 13:

- Do the same for the vertical sections

Step 14:

- Remove/hide unwanted elements, leaving only the lines for "export to cad format"

Step 15:

- Create joints (think of how the pieces should be joined together)

- I use clipping system for my vase, i.e. split the vertical sections into half such that they can clip onto the horizontal sections.

Step 16:

- Create PDF(s) for laser-cut

The appointment for laser is on Monday morning 11am. I hope everything goes well without major accident. More images after completion.

Tuesday, 28 July 2009

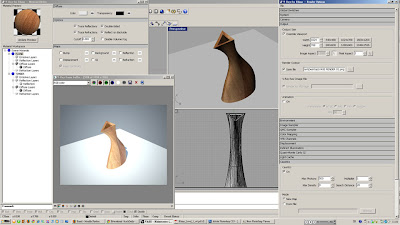

090728 Vase Transformer

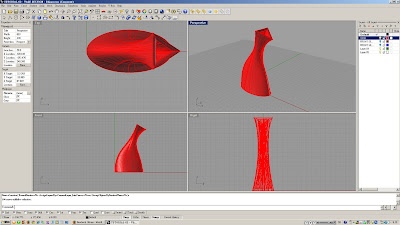

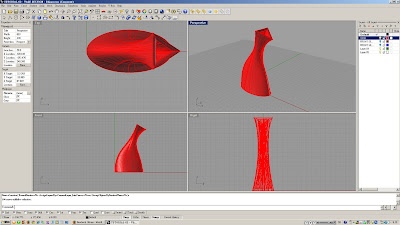

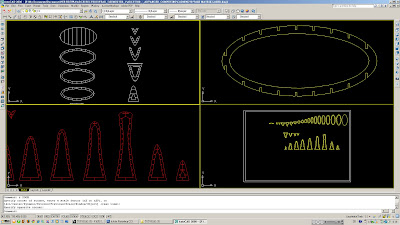

We have to design a vase for our 1st tutorial exercise. This vase is going to be 3d printed or laser cut on Wednesday 090729. I think my vase is going to be 3d printed. Basically, the vase has a simple design which is lofted with basic geometry.

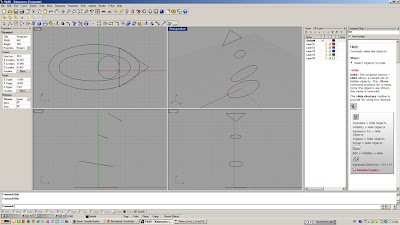

Step 1

- Draw 2 ellipses, 1 circle, 1 triangle within 50mm x 50mm grid extend

Step 2

- Offset each shapes by 1mm

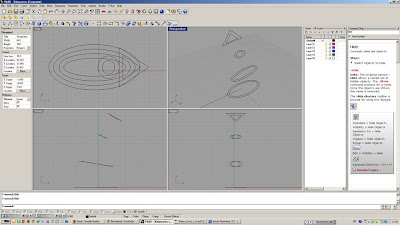

Step 3

- Select all inner shapes and loft them

Step 4

- Select all outer shapes and loft them

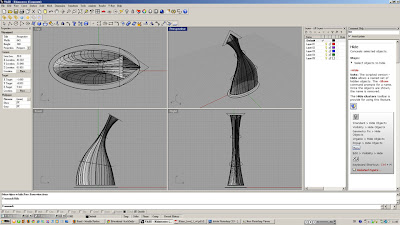

Step 5

- BlendSrf the top of the vase with default blend mode

Step 6

- Draw a CutPlane prepare to create the capacity for the vase

- Trim the inner lofted surface

- Create surfaces for the base by using PlanarSrf

Step 7

- Draw a base plane with PlanarSrf

Step 8

- Apply timber material to the vase

- Apply light grey diffuse colour to the base plane

- Render the vase with V-ray with caustics On

Duration: 120 minutes

Subscribe to:

Posts (Atom)