I have been working on Skyscraper 03 for more than 12 hours and finally I've got the scripts working, STL ready, and renderable. Pretty happy about the result to be honest. And hopefully the 3d-print will work perfectly fine for my 1:1000 model.

I will go through the process from here on.

Imported the mapped-points-drawings into AutoCAD which the acquirement of points have been illustrated in the

previous post.

Started mapping up the highlighted points using dots and crosslines.

Here's the results for the 4 categories

I decided to use square panel for the dots. The facades of the tower are also laid out with 10m x 10m square grids

Array across the panels with the 4 block panels. Rotate them to give more variations on the facades

It seems that 10m x 10m will contain a lot of points. So I made the grid to 20m x 20m and the density of points is just about right

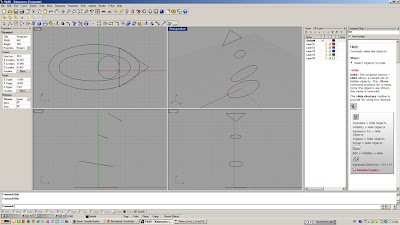

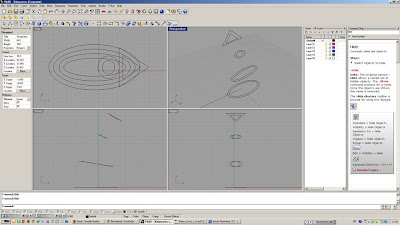

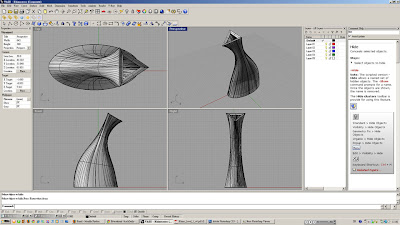

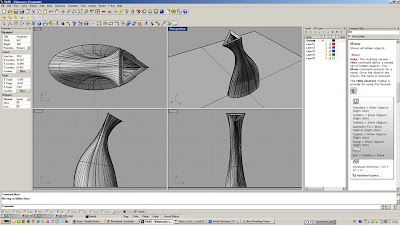

Import the dwg/dxf file into Rhino

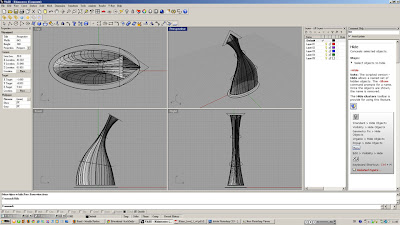

Applied Voronoi-2D script on facade and started to create some floor plates.

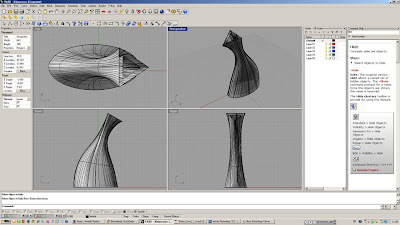

The wireframe generated by Voronoi-2D is then imported to 3ds max for piping (i.e. making from lines/curves to solid/mesh)

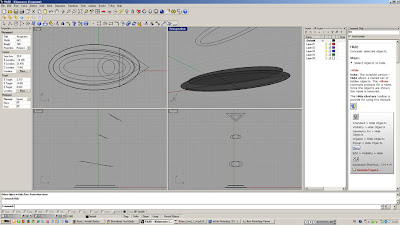

Isolated the wireframe to reduce memory usage for Scripts

I have modifed the script that I wrote in the

previous post. This script is more simple. What it does is considering

-> each cell as individual

-> offset curve inward

-> CurvethroughPolyline

-> clean up the scene

This script can be made much better in terms of the return and the input variables.

Then I did a simple PlanarSrf command by selecting all curves in the scene to create the cutout surfaces

I wrote another script for this particular move - Extrude each surface to its normal.

Each surface has their own normal of extrude. If you type in ExtrudeSrf and select all the surfaces, you might encounter a problem where some surfaces might extrude along the construction plane which is undesirable. So this script does:

-> enter extrude height value (preset Cap and Both sides prior to runscript)

-> considering each surface

-> extrude individually via its normal

-> clean up the scene

It runs quite a while and this is the result with a thickness for the "membrane"

This image shows the combination of the primary cell structure + the membranes

Playing with the shapes of the floor plates

And stack them up with a rotating configuration. The idea here is to create some double volume spaces.

Here is the overall model!

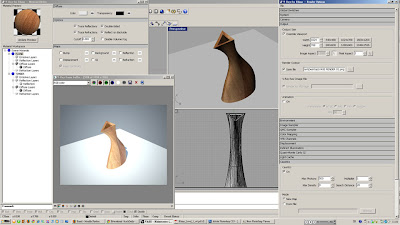

Import the whole model into 3dsmax for basic renderings

Rendering in process... and below are the resulting renders.

I like this render the most.